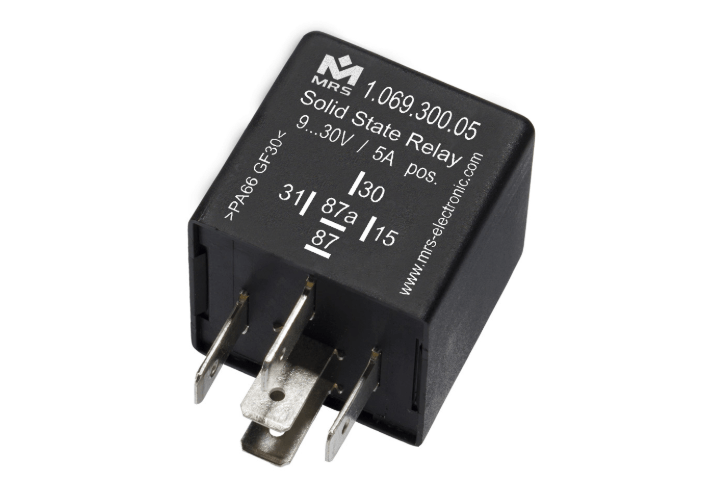

Solid State Relays: Enhancing Industrial Efficiency

What is a Solid State Relay

A solid state relay (SSR) is an electronic switching device that allows automatic control of electrical loads without mechanical components. Unlike electromechanical relays (EMRs), SSRs use a semiconductor technology like thyristors, triacs, or SSRs, that switches circuits on and off with the use of electric signals, offering faster operation, greater reliability and a longer service life.

Built using these principles, SSRs are now widely used in industrial automation, heating automation, motor drives and more. Their excellent capability to handle high switching frequencies without electrical or physical wear makes them a typical solution for industries that want to enhance efficiency while minimizing maintenance activities. SSRs, unlike traditional relays, can function silently and hold durability to external vibrations, which is suitable in extreme conditions.

How Solid State Relays Work

Solid State Relays operate by applying the control input of a signal into an electronic switching element. This working process can be broken down in three substages:

– Input stage: SSR is activated with a control signal from a microcontroller or from a microcontroller based control logic relay board.

– Isolation stage: Optical isolation (opto-couplers) isolates the control circuit from the load circuit, eliminating the chance of electrical manipulation to increase safety.

– Output stage: The connected load and the control signals of the components circuit turns on and off through the use of a semiconductor switch (triac, thyristor, or IXFH).

Because SSRs do not use mechanical parts, they do not have any moving components, which means they do not suffer from mechanical wear or arth-related failures. This greatly increases the performance in tasks that need high-speed switching or operation, like industrial heating or motor control. SSRs are better suited for an industrial automation environment.

Applications in Industrial Automation

Motor and Pump Control

Solid state relays also help engineers control the switching of industrial pumps and motors. SSRs provide exact switching control, thus reducing power losses. This loss is further reduced in automated processes where SSRs support smooth running of motors by controlling the speeds and loads of the motors. This also helps address the sudden spikes in voltages that might arise and damage equipment.

Also, SSRs help in implementing soft-start modes, where power to motors and pumps is increased gradually to reduce mechanical stress. This helps improve the lifespan of the equipment and adds safety in the water treatment, chemical manufacturing, or food processing industries.

Heating and Temperature Control

SSRs are performers for fueling temperature control in industrial use case scenarios with ovens, injection molding machines, and furnaces. As these machines are being used with different products, being able to quickly control power to heating elements ensures temperature control to maintain the product quality.

SSRs also do not emit electrical arcs, which makes them perfect for cases where there are minimal contamination environments that other relays can handle.

The operation of semiconductor manufacturing and pharmaceutical manufacturing industries is enhanced through their clean and reliable operations.

Lighting and Power Distribution

Industrial lighting systems often require relays that can handle high switching frequencies. The lighting control of the LEDs and the high-intensity discharge (HID) lights is taken care of by Solid State Relays (SSRs) thus ensuring proper dimming and power management without flickering. In big automatic facilities, SSRs also help in the efficiency of energy savings.

As for SSRs intended for electric energy distribution, SSRs are utilized for load balancing and control of surge voltage. They respond faster to dip or spike of power current than electromagnetic relays and thus help prevent electric failures in factories and commercial buildings.

To get high standard power switching solutions, check this page: https://www.omchsmps.com/es/path/switch-mode-power-supply/

Advantages of Solid State Relays

These SSRs differ from the traditional electromechanical relays in many ways hence their preference in use in industrial applications like:

– Longer lifespan – More durable because there are no mechanical parts to wear and tear.

– Silent operation – SSRs are voiceless unlike mechanical relays which produce noise when switching loads.

– Faster switching speed – In automation, it allows operations which require high frequency.

– Greater reliability – Possibility contact failure due to oxidation and pitting is lowered.

– Resistance to shock and vibration – Offers stability in industrial application embedded environments.

These benefits make SSRs ideal for applications requiring high-speed and high-reliability switching, particularly in sectors where minimizing maintenance costs is crucial.

Read also: Virtual Assistant Services for Remote Administrative Support: A Comprehensive Guide

Choosing the Right Solid State Relay

There are different options to choose from when it comes to solid state relays (SSR) that will be utilized at an industrial level. The following guidelines will help to pick out one:

– The kind of load and its voltage: Pick out whether there is a need for switching AC or DC power. Select an SSR that has the correct voltage and current specification.

– Heat removal: Most SSRs operate at a high temperature, therefore, significant SSEs must be fitted with a proper heat sinking or cooling systems.

– Features of isolation and safety: Select SSRs with overvoltage and short circuit protection features alongside thermal overload restraints.

– Required switching speed: Provide for systems which switch at high speed for automation purposes. These devices must be selected to ensure that they can deal with automation systems.

– Surrounding conditions: Pick SSRs meant for rough environments when working with very low or high temperature, and places where there is a lot of vibration.

In so doing, picking the right SSR device will guarantee improved productivity, minimization of downtime, alongside safety in all industrial activities.

Through having enhanced toughness, speed, and the ability to withstand rough and harsh environments, solid state relays have proven to be more effective than traditional mechanical relays. Their scope in industrial automation, heating, motor driving, and power distribution demonstrates their importance in modern electrical systems.

With the mechanism of automatic and smart technology adoption in the industries, the role of SSRs in control of power in an efficient manner cannot be understated.

Before deciding on vendors for industrial electronics, companies seeking superior SSRs should take a look at the providers from OMCH. These firms can benefit from the innovative uses of solid state relays as they enhance performance, reliability, and lower the costs for maintenance.