The Importance of CNC Milled Parts in High-Precision Manufacturing

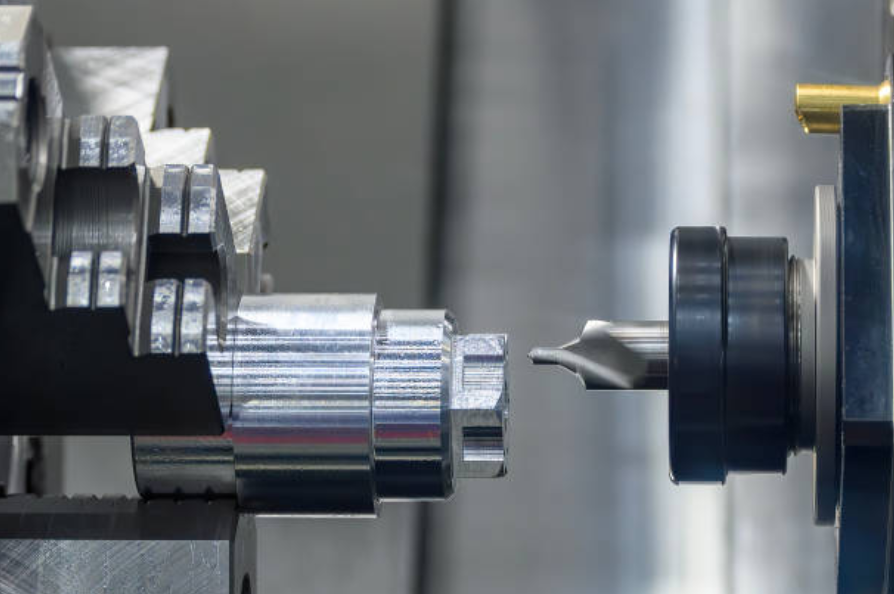

Like any nano tolerant process, CNC machining is both precise and reliable. There has been a considerable increase in demand for CNC machining in complex intricate components which have tight tolerances for several different industries. These components are critical for the manufacturing of machines, apparatus, or tools in fields like aerospace, medical devices, automotive, electronics, etc. It is now standard practice to use CNC Milling due to its ability to achieve accurate CNC geometries and superior surface finish.

CNC precision parts suppliers are especially important in maintaining the supply of these components. He or she makes sure together with his or her skilled personnel that all components are manufactured to the significant standards of different industries. This article will discuss CNC milling in the context of high-precision manufacturing and the role of CNC precision suppliers in supporting business surgical objectives.

The Role of Precision Machined Parts Suppliers

Precision machined parts suppliers are the backbone of the CNC milled parts industry. These suppliers provide the expertise, equipment, and materials necessary to create high-quality, precise components. They ensure that every part meets the technical specifications required for its application, whether it’s for aerospace, automotive, or medical devices.

One of the key advantages of working with precision machined parts suppliers is their ability to provide custom solutions for unique challenges. CNC milling can produce highly specialized components, and suppliers often work closely with businesses to understand their specific needs. This collaboration ensures that the parts produced are tailored to the exact requirements of the project, improving overall performance and quality.

Moreover, precision machined parts suppliers are equipped with advanced CNC milling machines capable of achieving tight tolerances and complex geometries. With their state-of-the-art equipment and highly skilled workforce, these suppliers can deliver precision components that meet the most demanding standards.

See also: High-Speed Thread Milling: CNC Advancements for Large-Diameter and Deep Threads

The Advantages of CNC Milled Parts in High-Precision Manufacturing

Due to the myriad advantages CNC milled parts offer, they are central to high precision manufacturing. These advantages not only aid the process of manufacturing but also enhance the quality and performance of the product being manufactured. Here are some of the critical advantages of CNC milled parts in high precision manufacturing.

Primary Importance And Merit Of Precision And Accuracy

Achieving astonishing levels of accuracy is perhaps the most important merit of CNC milled parts. Their precision is made possible by the use of computer controlled CNC machines which follow pre-set specifications to the level of microns. Such unparalleled precision guarantees that CNC milled parts exceed the stringent tolerances needs by sectors like Aerospace and Medical Devices, where even the slightest inaccuracies can cause catastrophic failures or malfunctions.

For instance, users in the aerospace sector often have engines and aircraft system components manufactured which have to be pushed to the utmost limit in regards to safety, performance, and other factors. CNC milled parts are essential for meeting the acute precision required in these applications.

Complicated Designs And Geometries

CNC milled parts have the distinct advantage of adding intricate details to complex designs, something that was previously unheard of. Such components would be impossible to make using traditional machining techniques, but CNC milling is capable of making even the most complicated shapes effortlessly handleable.

Because of the precision achieved by advanced CNC machines, they are useful in geared towards sophisticated industries like medicine where interfaces require curvature, undercuts and intricate detailing such as complex holes.

The ergonomic strategy used in surgery suggests that instruments need to be sculpted to maximize far more than functionality. Design complexity does not suffer from access and CNC machined parts demonstrate precise and efficient means of achieving intricate designs.

Material Flexibility

CNC machined parts can be created from practically anything including metals, plastics, and composite materials, which makes it imperative to industries that endure specific stressing conditions. These include, but are not limited to aerospace-grade aluminum, Titanium, and high-strength Polymers.

An illustration of such is in the automobile industry where CNC machined parts are widely utilized for elaborate but lightweight sturdy constructions like engine blocks, suspension parts, or durable transmission components. The wide range of materials ensures industry-grade precision offered by CNC machined parts suppliers can be met with the ever-growing demand spanning countless applications.

Cost and Time Efficiency

When compared to traditional machining processes, CNC milling saves a substantial amount of time and money. There are quicker production cycles and reduced human intervention as a result of automation offered by CNC machines.

As a result, precision machined parts suppliers are able to emplace cnc milling on parts and deliver them faster, reducing lead time and improving efficiency.

Also, the chances of making an error are reduced, making the parts more accurate with fewer defects and rework. Businesses save money on defective parts that are too damaged to be repaired or need excessive scrapping.

CNC Milled Parts in Key Industries

Industries that rely on the manufacture of CNC milled parts require that they perform with the utmost accuracy and are very sophisticated and consistent with the design. Some of the primary industries that depend on CNC milled parts are as follows:

Aerospace

CNC Milling is widely used in the manufacturing of turbine blades, landing gears, and other structural components in the Aerospace industry. Torque and quality limits has to meet tossed standards for the parts to be safe for use. The Suppliers of precision Machined Parts within the Aerospace sectors need to have developed capabilities to manufacture such parts within these limits.

Automotive

CNC milled parts are also needed for the manufacture of automobile components including engines, chassis, and suspension systems. CNC milled parts have always been in great demand, particularly in electric and performance cars. These vehicles have an increased need for lightweight components that are strong at the same time. For these specialized applications, there is always an unending urgent need from Precision Machined Parts Suppliers.

Medical Devices

In the medical equipment industry, components are expected to be very reliable in crucial situations, and hence CNC milled parts have check any requirements. CNC milled components can be used to manufacture intricate designs surgically as well as with greater degrees of accuracy such as implants.

Producing medical device components with tight tolerances is critical for patient safety and the proper functioning of the devices.

Electronics

In electronics, CNC milled parts are used in the manufacture of casings, connectors, and other peripherals. These components are CNC milled due to the precision associated with them. All parts are interlockable and fulfill their designated mechanical function within the electronic device, therefore inline with safety requirements and standards.

The Future of CNC Milled Parts in High-Precision Manufacturing

The demand for CNC milled parts is expected to continue growing as industries increasingly require high-precision components for advanced applications. Precision machined parts suppliers are constantly developing new technologies and techniques to meet the evolving needs of industries such as aerospace, medical, automotive, and electronics.

The future of CNC milling is closely tied to advancements in automation, artificial intelligence, and additive manufacturing. As these technologies continue to develop, CNC milled parts will become even more precise, efficient, and cost-effective. Businesses that invest in these innovations will gain a competitive edge in the global market.

Conclusion

Offering clear versatility and efficiency, CNC milled parts are vital components in high-precision manufacturing due to its unparalleled accuracy. Various industries have diverse and sophisticated CNC machined parts requirements; thus, precision machined parts suppliers are increasingly important to provide the parts for high demand. There is ever-growing attention directed towards CNC milled parts due to the increasing complexity multipurpose components have across industries.

The landscape of CNC machined components is very competitive, which makes understanding the advantageous capabilities of the design integral to staying ahead in the business.