What Is a Switching Power Supply? Exploring Its Role in Modern Electronics

The technology sector has grown tremendously over the years. As a result, designing power systems that are both reliable and easy to control has become paramount. Switching power supply (SPS) is vital for the performance of many modern electronic devices and systems, primarily in industrial automation. SPS’s are essential for the system’s performance and efficiency, whether the application is in robotics, manufacturing systems, or automation control systems. This article discusses what switching power supplies are, what they do, and their significance in modern electronics, particularly in industrial automation systems.

What Is A Switching Power Supply?

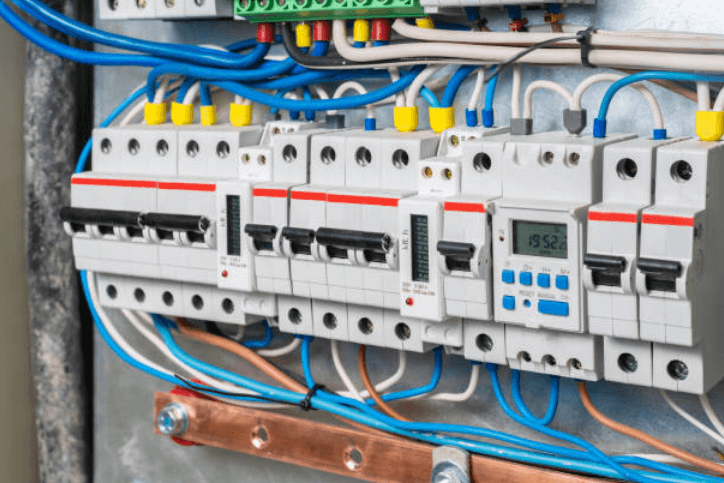

Switching power supply is a type of device that contains a power supply unit that can convert energy from one form to another in a highly efficient manner using changeover switches. In comparison to other power supply units, switching power supply units use a high speed power switch to control the output voltage. These switching regulators function much more efficiently than traditional linear power supplies that rely on super heating a coil to create electricity. The heat generated during the process is a lot less than the amount of heat given off and is lost, so in some processes, it is rather ideal to have an industry automation system where the excess heat is not very much.

From consumer electronics to complex industrial equipment, switching power supplies are utilized in various electronic devices. These power supplies are very useful in applications that consider energy and space constraints, as well as dependable performance. For automation companies, employing a switching power supply means that the system functions optimally, minimizing the chances of idle time which in turn increases productivity. In addition, the rapid switching enables these power supplies to keep pace with various working conditions and changes in voltage, thus maintaining stable output.

Advantages of Switching Power Supplies

There are benefits and advantages that come with using switching power supplies that make them favorable to use for industrial automation companies and other electronics applications. One of the primary advantages is their high efficiency. Unlike linear power supplies which dissipate excess energy as heat, switching power supplies use energy far more efficiently by increasing the ratio of usable power. This is especially crucial in industrial automation, where tremendous power consumption is needed to run large machines and systems for a long duration of time.

Another distinct aspect is their small proportion. Unlike linear counterparts, switching power supplies are smaller and lighter because they do not require large components to dissipate energy. This provides a benefit in situations where space is constrained. With that said, compact size allows easy integration into various industrial automation solutions such as robotics, conveyors, and control systems. Furthermore, their adaptability is aided by the fact that they can accommodate a wide range of input voltages.

As the efficiency of power sources increases, their overload and short circuit protection systems become more prominent. For one, these features improve overall reliability and increase safety for the end user. These new protection systems ensure smooth operations of systems powered by switching supplies under a myriad of conditions, helping safeguard against high risks of equipment failure and costly downtimes for industrial automation companies.

Switching Vs. Linear Power Supply: Key Differences

There are several major differences when switching power supplies are compared to linear power supplies. The difference that is most apparent is efficiency. Switching power supplies tend to be more efficient as compared to linear power supplies, which tend to be less effective in comparison. This statement is true because linear power supplies waste energy in the sense of losing it in the form of heat, while switching power supplies encapsulates the energy with almost no waste.

The effectiveness of a switching power supply has a direct impact on and reduces energy costs while increasing system reliability for an industrial automation company. Although linear power supplies are preferred in industries needing ultra-clean output and low electromagnetic interference, most industrial environments have realized the benefits of switching power supplies and have adopted them for use.

Another major distinction that most people tend to forget is the size. In industries where space optimization is critical, low and light switching power supplies are ideal as compared to the bulky linear power supplies. This reduced size also allows for more effective system designs in industrial automation systems while simultaneously saving valuable space and ensuring peak performance from the equipment. Furthermore, the increased efficiency of switching power supplies leads to reduced heat generation, thus eliminating the need for extra cooling systems and lowering operational costs.

Why Switching Power Supplies are Essential for Industrial Automation Companies

The application of a switching power supply has many benefits for industrial automation companies. Switching power supplies saving energy translates into a reduction of energy costs, helping businesses save on electricity bills, without having to lower the performance of the systems. The power supplies are small which means that they can be installed in compact places, which is very important in modern automation systems where space is limited.

Another advantage is the reduction in the requirement for cooling. The reduced heat output of switching power supplies compared to linear power supplies means that they do not need high capacity cooling systems to deal with excess heat. This approach not only cuts operational expenses, but also increases the dependability and durability of the equipment.

In addition, switching power supplies accept a wide range of input voltages providing increased adaptability to different configurations and settings. This allows industrial automation companies to apply these supplies on different machines and systems which increases flexibility while decreasing the number of power supply units that are needed. Increased reliability and cost efficiency make these supplies enticing to businesses that want to enhance their power systems without sacrificing performance.

Read also: How Large-Scale Manufacturing Drives Cost Reduction in Furniture Hardware

Conclusion

It is highly likely that integrated circuits would not have existed were it not for the advancement in switching mode power supplies. Everything from power management in telecommunication transmitters, power supplies for instruments, desktop computers and processors are dependent on this technology. Among the myriad of its applications, the most multifaceted nanotechnology devices and the piezoresistive sensors and actuators, which are at the forefront of modern electronic devices, would have been too complicated to miniature without sophisticated condense technology. The importance of this technology will continue to expand without boundary growth of microelectromechanical systems. On their own, MEMS can act as actuators and sensors, but at the same time require advanced and just as miniature electronics for power management and signal processing. Switching power supplies are crucial in the advancement of the electronic and machinery industry.